- 16

- Jan

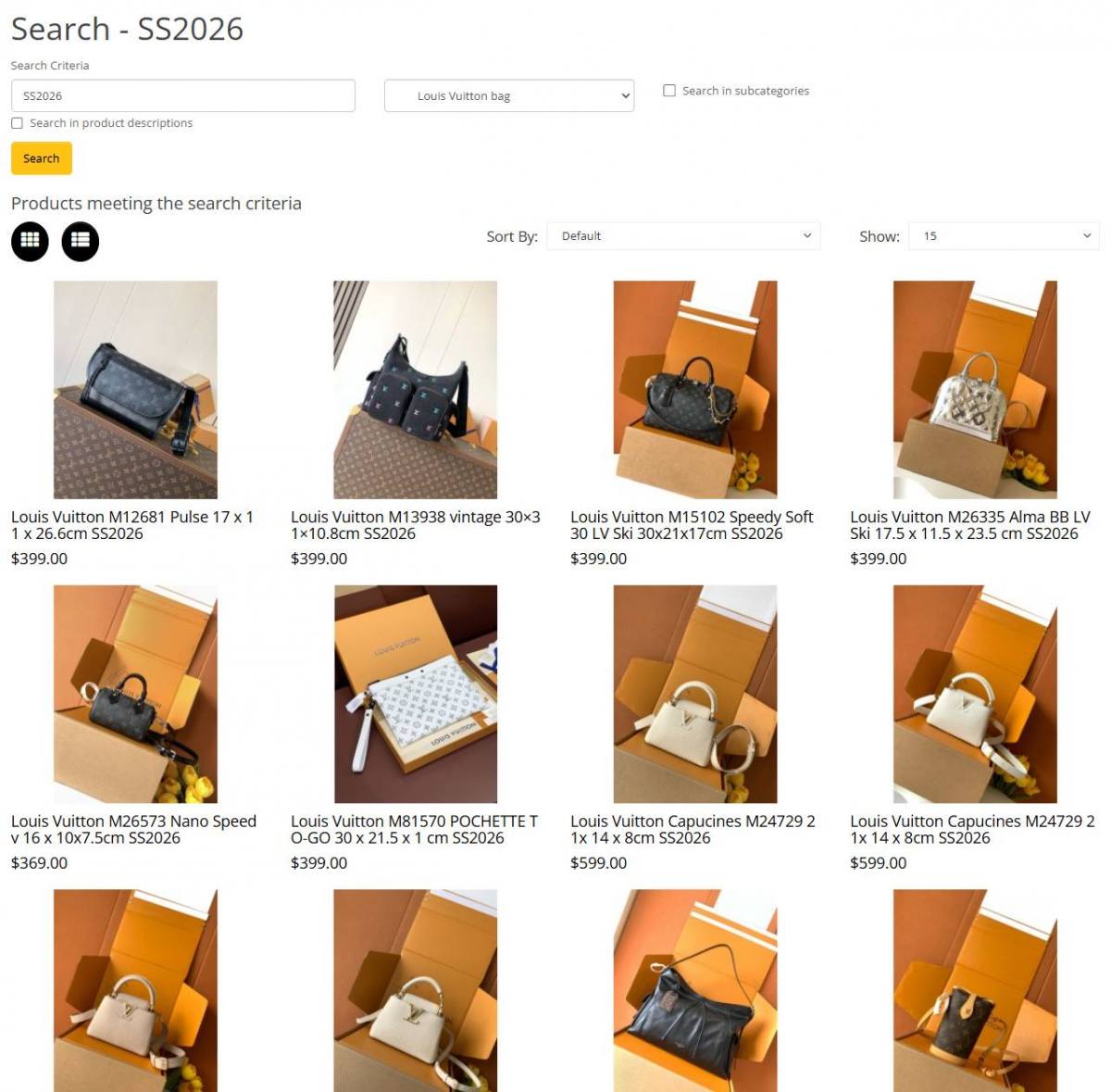

Shebag 2026 Louis Vuitton bags collection(Jan 2026 updated)

Louis Vuitton top-tier replica bags represent Shebag’s highest sales volume. Even though Shebag is renowned for its Chanel leather bags, LV’s Monogram bags are absolute classics. Since Shebag can perfect top-tier leather for Chanel and Hermès, mastering LV’s Monogram coated canvas is a comparatively easier task.

However, producing LV’s Monogram coated canvas is not entirely simple. Although Shebag does not manufacture the Monogram coated canvas itself, we conduct rigorous factory inspections and manage quality control during the intermediate stages to ensure the result is exactly the same as the authentic LV Monogram.

Today, we are sharing our technical understanding of the craftsmanship behind Monogram coated canvas.

LV’s Monogram is a classic—a special type of coated canvas that is waterproof, oil-resistant, and anti-aging. Its surface features irregular protrusions, and it makes a hard, crisp sound when scratched with a fingernail. Almost all classic models use Monogram fabric. To prevent replication in China, LV places Monogram production in Europe, but the raw materials—such as resins, pigments, additives, and base fabric yarns—are sourced from Japan and South Korea.

1. The Definition of the Material

LV Monogram Coated Canvas is one of Louis Vuitton’s most representative core materials, widely used in classic series like Speedy, Neverfull, Alma, and Keepall. This material is not leather, but a highly engineered composite material system. Its true value lies not in the pattern itself, but in the surface treatment process, the stability of the coating system, and the capability for long-term consistent industrial control.

2. Structural Composition

LV Monogram belongs to a typical “coated canvas” (toile enduite) structure.

- The Substrate: Its foundation is a high-density base fabric, traditionally cotton-based, though some eras or batches may use a cotton-polyester blend to enhance dimensional stability and resistance to deformation. The base fabric itself is not directly exposed to the external environment; its function is primarily to provide mechanical strength, tear resistance, and structural support during bending.

- The Coating: The surface of the base fabric is covered by a multi-layer resin coating system. The core objectives include water resistance, oil resistance, stain resistance, abrasion resistance, anti-aging, and maintaining shape stability over long-term use. This structure determines that Monogram feels, sounds, and performs more like a “hard coated material” rather than a “textile” or “leather.”

3. Surface Texture and Sound

The Monogram surface is often described as having an irregular but uniform graininess, visually resembling leather texture, but with a harder touch. When lightly scratched with a fingernail, it produces a clear, crisp “hard sound.”

- The Texture: During the coating formation process, the resin system undergoes hot pressing under controlled temperature and pressure using embossing rollers or molds to form a stable texture structure. This texture is not perfectly regular but is a designed “faux leather grain.” Its functions include minimizing surface scratches, improving abrasion resistance, enhancing visual depth, and masking inevitable minor flaws from the printing process.

- The Sound: The hard sound emitted when scratched by a fingernail is essentially the friction between the nail and the high-hardness resin coating, not contact with fibers. This is a key sensory characteristic distinguishing coated canvas from ordinary fabrics or soft coated materials.

4. Printing and Integration

The classic Monogram pattern is not woven but achieved through a high-precision printing system.

- The Process: The logical process flow is usually: first completing the base fabric and main coating structure to ensure stable physical properties and texture; followed by multi-color overprinting to precisely print the pattern on the coating surface or intermediate layer; and finally covering it with a transparent or semi-transparent protective topcoat to lock in the ink and enhance resistance to chemicals and wear.

- The Result: This structure means the pattern is not simply “printed on top,” but is integrated into the entire coating system, allowing it to remain stable under long-term friction, bending, and environmental changes.

5. Factory Quality Control Indicators

From a factory quality control perspective, LV Monogram coated canvas is a highly engineered material system. Its quality is not determined by a single process but constrained by multiple key control indicators.

- Coating Thickness & Hardness: These are central to control. Thickness determines stiffness and stress distribution. If too thick, the bag will whiten or crack at folds; if too thin, it wears out easily. Hardness must be maintained in a “hard but not brittle” window—providing rebound feedback without snapping during repeated bending.

- Adhesion Force: The bond between the coating and the base fabric determines lifespan. Insufficient adhesion leads to bubbling, delamination, or peeling at edges. This depends heavily on the pre-treatment of the base fabric and the temperature/pressure curves during coating.

- Embossing Consistency: The depth and density of the grain must be within strict tolerances. Too shallow, and the texture looks “collapsed” or flat; too deep, and it creates abnormal shiny spots (plastic look) under side light.

- Printing Registration & Color Management: Monogram involves precise alignment of the brown base and the lighter motifs. Deviation leads to blurred edges. Color management is strictly controlled to prevent batch-to-batch variation.

- Chemical Resistance of the Topcoat: This determines performance against alcohol, perfume, sunscreen, and skin oils. Poor stability leads to stickiness, fogging, or color fading after months of use.

- Pattern Alignment (Craftsmanship): Even if the material is perfect, failing to follow the brand’s logic for pattern alignment (cutting the fabric so the logos align perfectly at seams and folds) is considered a failure in quality control. This requires a deep understanding of the brand’s visual order.