- 10

- Jan

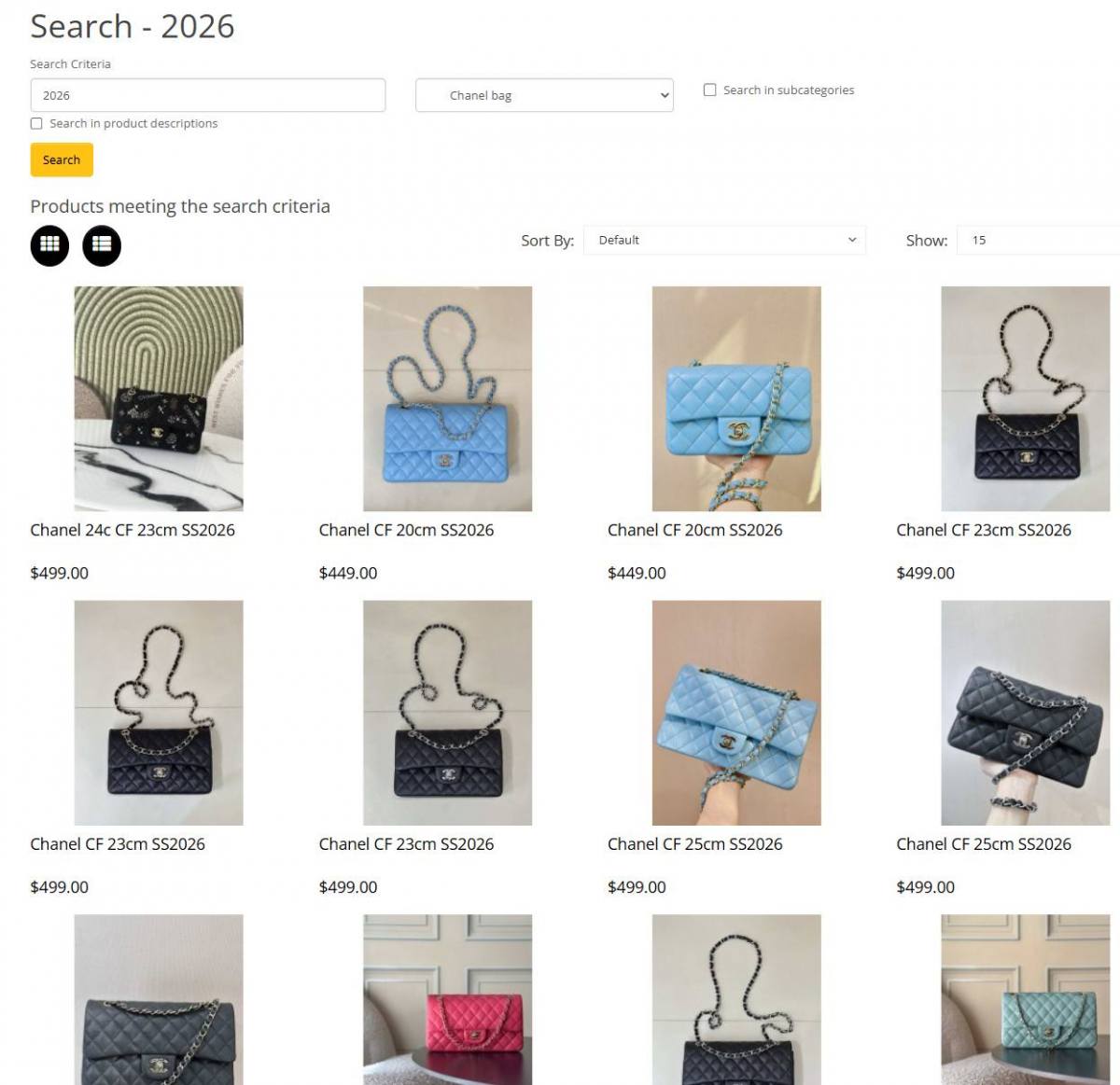

Shebag 2026 new batch Chanel bags (Jan 2026 updated)

Come check out the latest Chanel models Shebag is currently producing!

That’s right—the bags currently on our production line are primarily Classic Flaps (CF). We are focusing mainly on the Medium 25cm, but also the Small 23cm and the Mini Square 20cm. We are also producing many new styles featuring the Golden Ball, Gold Buckle, and Gold Bead adjusters. These are available in both Caviar leather and Lambskin, featuring many new colors and hardware options including Gold Hardware (GHW), Silver Hardware (SHW), and the highly fashionable Champagne Gold.

Many of our long-term clients are now purchasing CF bags in Champagne Gold, as they already own the standard Gold and Silver hardware versions. Today, Shebag will reveal a glimpse into our manufacturing craftsmanship for Chanel’s Champagne Gold hardware. We welcome competitors to imitate us, but rest assured: imitators will never achieve Shebag’s level of craftsmanship.

The Champagne Gold and Pale Gold (Light Gold) hardware used on the Chanel Classic Flap are not merely single “color options,” but a complete metal craftsmanship system built around visual restraint, sophisticated texture, and long-term durability. The essential difference between these two colors lies not in “how gold they are,” but in the systematic control of saturation, reflectivity, warm/cool bias, and surface energy.

1. Defining the Colors First, it must be clarified that the Champagne Gold and Pale Gold used by Chanel are not simply “renamed gold hardware” in the marketing sense. They are two stable color gamuts formed based on the same metal structural system through different plating parameters, surface treatments, and sealing strategies.

- Champagne Gold is gold that has been “suppressed, cooled, and atomized.”

- Pale Gold is gold that has been “diluted, thinned, and neutralized.”

2. The Substrate (Base Material) In the supply chain, the core substrate for CF hardware remains primarily high-purity brass. The advantages of brass lie in its uniform metal structure, good ductility, high polishability, and stable adhesion to the color layer during plating. For high-visibility components like turn-locks, plaques, chain links, and logo ornaments, we prioritize brass systems with stable copper-zinc ratios and extremely low impurity content, rather than cheap zinc alloys. This is because the plating layers for Champagne and Pale Gold are relatively thin, making them extremely sensitive to the base material’s color and surface smoothness; any redness or roughness in the substrate will directly affect the final tone.

3. Blank Manufacturing The blank manufacturing stage typically employs precision casting combined with localized CNC or stamping processes. The main body of the turn-lock and internal structures are mostly cast and then machined; chain links are often stamped, stretched, and welded closed; screws and cores are turned parts. The focus at this stage is not color, but geometric precision and surface integrity, as subsequent polishing and plating will magnify any structural defects.

4. Surface Pre-treatment (The Key to Luxury) Before any color is formed, the step that truly determines the sense of luxury is surface pre-treatment. The requirements for Champagne and Pale Gold are far higher than for bright gold. After the blanks are finished, they undergo multiple rounds of deburring, vibration polishing, and manual trimming before entering the graded polishing stage.

- Rough polishing removes casting textures and stamping stress marks.

- Medium polishing unifies surface curvature.

- Fine polishing creates a near-mirror metal base. It must be emphasized that even if the final goal is a matte Champagne Gold, the underlying polishing must be extremely fine. The matte effect is not achieved through “roughness,” but through subsequent controlled micro-atomization.

5. Divergence of Styles Champagne Gold and Pale Gold begin to diverge at this stage.

- Pale Gold usually retains higher underlying smoothness, with only localized or overall extremely slight brushing (or no atomization) to ensure metal reflection remains clear but not glaring.

- Champagne Gold, however, receives an ultra-fine particle micro-sandblasting or chemical atomization treatment after fine polishing. This treatment is almost invisible to the naked eye, but it effectively diffuses mirror reflections, giving the metal a soft, low-contrast luster.

6. The Plating Process Entering the plating stage, color differences are further amplified. Before formal color plating, parts undergo electrolytic degreasing, acid activation, and multiple pure water rinses. They then enter the base plating system. The base layer is typically a composite underlayer: a copper layer for leveling micro-pores, and a nickel or palladium-nickel layer for corrosion resistance and to block the substrate color. For Pale and Champagne Gold, the uniformity of this underlayer is critical; if uneven, the substrate’s color will bleed through.

7. Color Layer & PVD Color layer plating is the core of color formation.

- Pale Gold typically uses a thin gold or gold alloy plating layer, controlling current density, time, and solution formula to achieve a pale, neutral state.

- Champagne Gold employs a more complex tonal calibration, including lowering gold phase saturation, introducing a slight cool tendency, or altering reflection characteristics via post-processing.

- PVD Option: For components with higher wear resistance requirements, a PVD (Physical Vapor Deposition) vacuum coating system may be used. Titanium nitride films create the gold tone, which is then adjusted to be lighter and cooler. However, even with PVD, achieving the soft feel of Champagne Gold requires superimposing an atomized or transparent sealing layer.

8. Sealing (The Invisible Layer) After the color layer is complete, almost all hardware enters the sealing process. This layer is visually imperceptible but decisive for long-term stability (clear lacquer, anti-fingerprint coating, or thin film). Its functions include lowering surface energy, reducing fingerprint residue, and blocking chloride ions in sweat. Champagne Gold relies heavily on this layer to “suppress brightness.” If too thick, it looks grey and plastic; if too thin, friction will polish it, creating shiny spots.

9. Assembly & Testing In the final assembly stage, the biggest challenge is multi-component color consistency. We implement strict batch management, requiring that all hardware (chains, locks, screws) for a single bag comes from the same color batch. Because Champagne Gold has a narrow hue range and is sensitive to light, it undergoes the strictest QC. Durability testing includes simulated chain friction, lock operation, artificial sweat, and salt spray testing.

From a craftsmanship perspective, the most common reason for failure with Champagne and Pale Gold is not the plating itself, but a lack of understanding of the overall system. Relying solely on changing the plating color while ignoring the synergy of substrate, polishing, atomization, and sealing results in an effect that “looks similar but fails in use.” Truly stable Champagne Gold is achieved through minute process adjustments based on extremely high surface quality.