- 03

- Nov

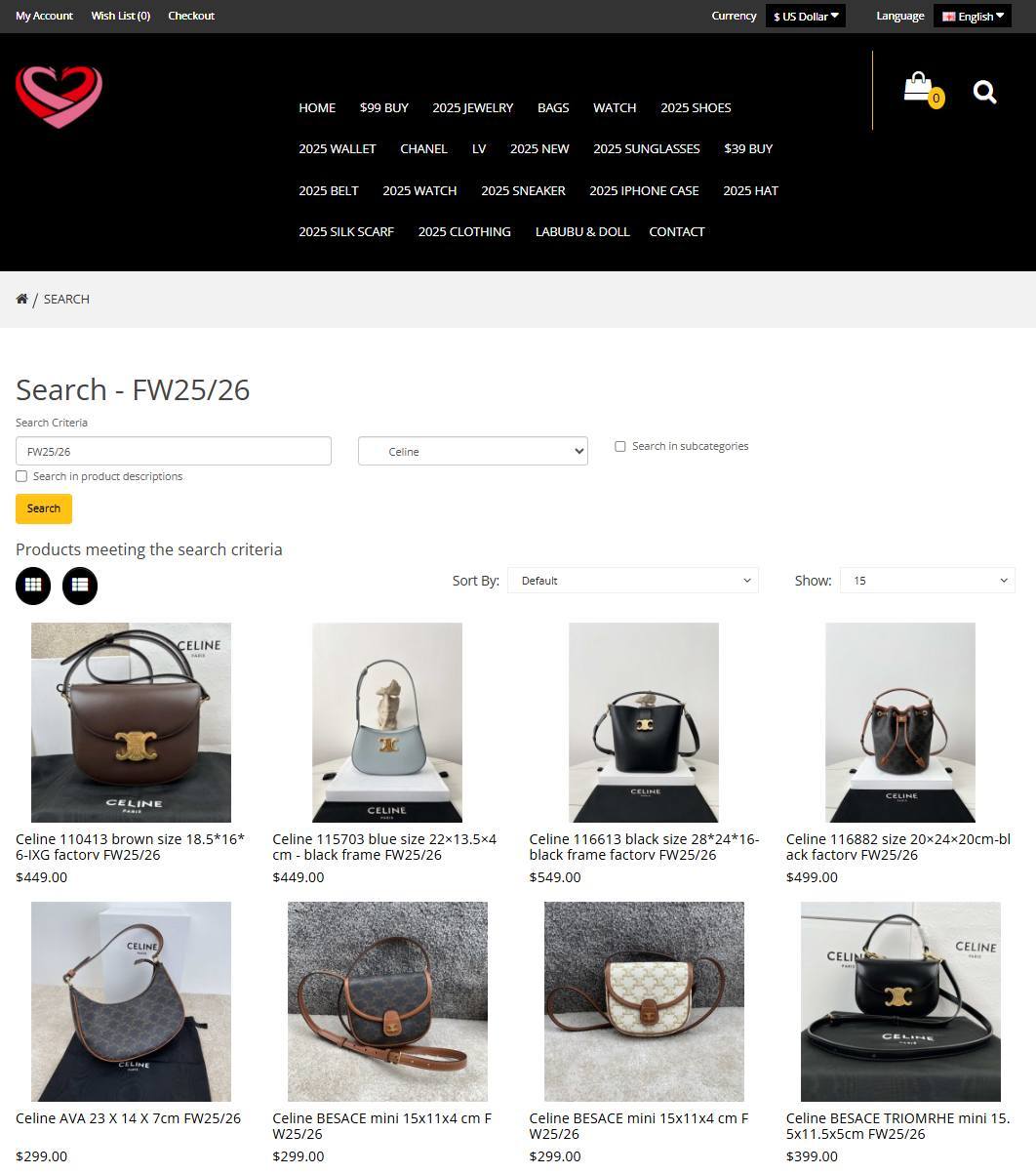

Shebag FW25/26 new Celine bags(Nov 2025 updated)

Link: https://www.cfbuy.ru/index.php?route=product/search&search=FW25%2F26&category_id=114

Shebag has produced and listed a new batch of Celine bags for the Fall/Winter 2025 season. While this includes new styles, the focus remains on Celine’s classic bags. Whether it’s canvas or leather, the raw material quality of Celine bags is significantly higher than that of Gucci and Goyard, providing a much stronger premium feel.

Unlike Hermès, Chanel, and Louis Vuitton—brands that either build their own ranches or acquire stakes in them to exclusively control their supply chains—Celine uses leathers from the open supply chain. This makes it much easier for Shebag to replicate Celine bags. Shebag utilizes the very same supply chain as Celine, just with smaller procurement volumes. Today, the Shebag factory is sharing its dismantling and analysis of Celine bags with you—all of which is our own exclusive research.

Celine meticulously selects leathers from top-tier European tanneries, such as Haas and Roux in France, and Tempesti in Italy. Common leathers include:

Box Calf: Fine-grained and firm to the touch, this is the classic material for the 16 Bag.

Grained Calf: Scratch-resistant and soft, ideal for daily use.

Supple Lambskin: Used for the Triomphe or Classic series, noted for its exceptional luster.

Natural Cuir Veau or Tumbled Calf: Lightly coated leather with a natural grain that shows variation in color.

Each batch of leather undergoes tests for elasticity, thickness, color consistency, and anti-deformation to ensure standardized structure and feel.

Cutting & Assembly: The leather is manually laid out and cut by senior artisans to minimize scars and color variations. Celine’s distinction is its continuation of traditional Hermès craftsmanship:

Hand-cut with cutting knives to ensure clean, sharp edges.Seams are joined using Saddle Stitch or double stitch; some models use machine stitching for structural symmetry.Edges are double-layered or reverse-folded, combined with wax thread edge finishing to resist friction and splitting.Stitch density is approximately 8–10 stitches/cm, with thread tension adjusted based on leather thickness.

Forming & Shaping: Celine bags, like the 16 Bag and Trapeze Bag, are often defined by their rigid silhouettes. Their structure comes from:

The leather’s inner layer is bonded with a fiber or ultra-thin vegetable-tanned leather support layer.Heat-press molding process: A hot mold (70–90 °C) is used to press and set the bag’s curves.The structural edge lines (“bone lines”) are reinforced with thin steel strips or nylon boning to ensure the bag’s opening does not collapse.

Hardware & Finishing: All hardware is custom-made from a brass base, which is then electroplated in palladium (silver), light gold, or antique brass.

The surface is reinforced with a PVD coating for scratch resistance and engraved with the CELINE logo.Edge paint is an Italian Giardini resin coating, which is applied and polished 3–5 times.Every finished piece undergoes manual QC inspection; no bubbles or scratches larger than 0.3 mm are permitted.

Lining & Assembly: The lining of Celine bags is typically:

Full Nappa or Suede leather (used in high-end series like the Classic Box).Fabric lining with leather edge piping (used in lightweight bags).

During assembly, the leather must rest and return to ambient temperature for over 12 hours to prevent cold shrinkage from deforming the stitches. All clasps and strap rings are calibrated by specialists to an angle tolerance of no more than 2°.