- 12

- Feb

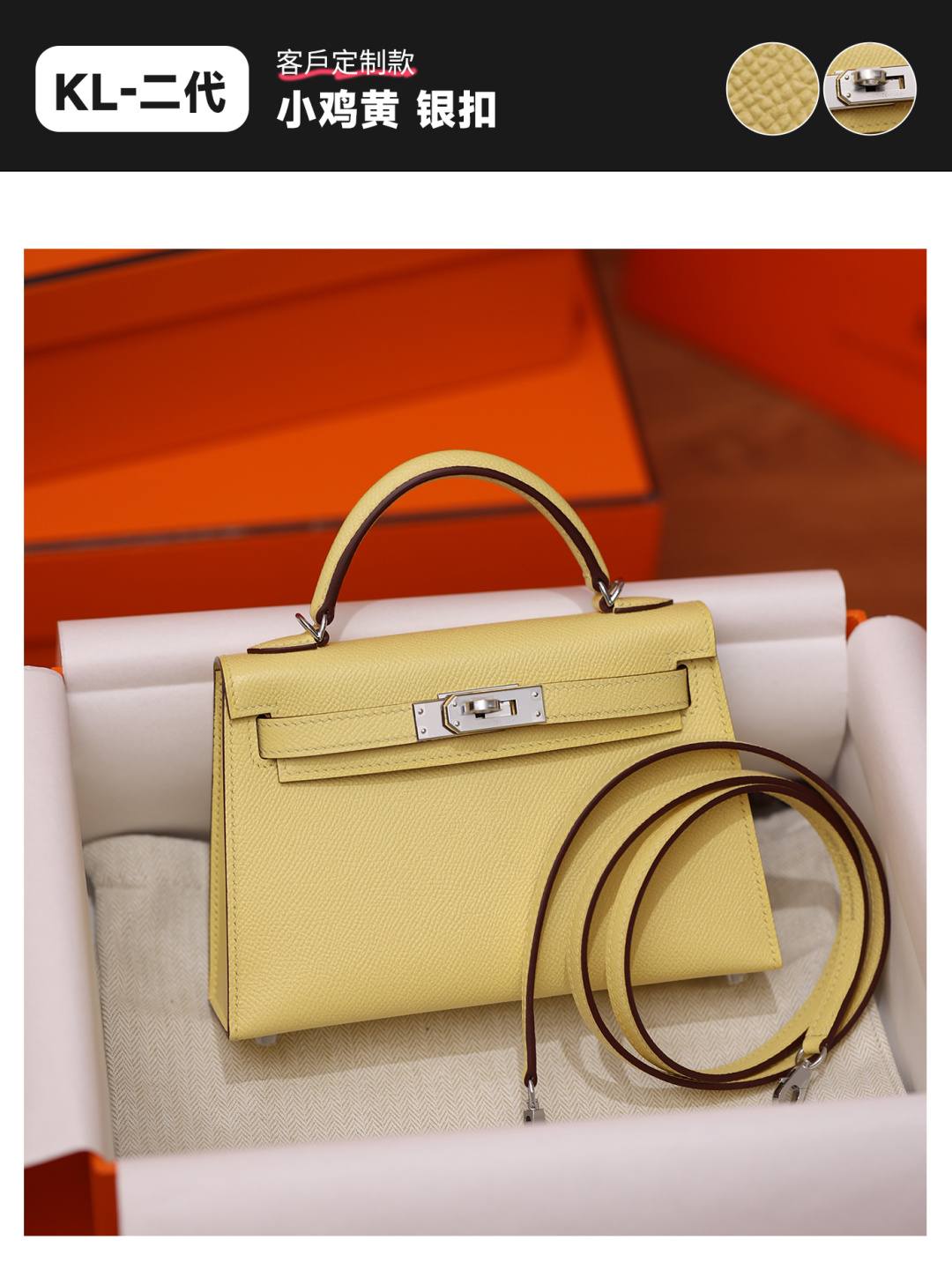

Shebag handmade Hermes mini kelly 2 bag in yellow epsom leather bag review(Feb 2026 updated)

The crust leather is sourced from the back of top-tier young bull hides from premier ranches in France, Germany, and Italy, featuring tight fibers, fine pores, and no looseness or scars. Only the best back section is used, with a hide utilization rate of approximately 60% and a rejection rate exceeding 50%.

The core supply chain relies on a small number of LWG Gold-certified tanneries, including Hermès-owned France Tanneries Du Puy (TDP), Germany’s Weinheimer, and France’s Haas. Long-term exclusive agreements ensure direct crust leather supply with no intermediaries. Hermès dispatches technical teams on-site to supervise the entire process: tanning, embossing, and dyeing.

The signature high-temperature and high-pressure cross-grain (Epsom grain) embossing creates uniform, crisp patterns that never collapse—an iconic feature of Epsom leather.

Finishing uses a thin resin coating plus a wax layer to deliver a semi-matte luster that is scratch-resistant and easy to maintain, ideal for daily use.

The entire supply chain is 100% made in France, with direct delivery from crust leather to tanneries and then to leather workshops. Each batch carries a unique batch code, traceable to ranch, slaughter, tanning, and artisan details, ensuring stable quality and anti-counterfeiting.

evenness for light tones, high transparency without dullness, lightfastness without fading, and compatibility with Epsom embossing. All parameters are strictly controlled.

High-purity metal-complex acid yellow dyes are used, together with special leveling and penetrating agents, to ensure the dye penetrates evenly into the fiber layer rather than floating on the surface.

Dyeing temperature is controlled at 45–50°C, over 2–2.5 hours, with slow and uniform drum rotation to avoid uneven dyeing or color variation.

After embossing, color correction and pore sealing are performed, with extra emphasis on the cross-grain grooves to ensure consistent color inside and outside the pattern. A transparent lightfast resin topcoat is then applied to block UV rays and prevent Chick Yellow from yellowing or darkening over time.

Every skin is inspected with a standard color card and colorimeter, with ΔE controlled within 0.5 to ensure perfectly uniform Chick Yellow across the same batch and different batches of Mini Kelly 2, creating a sophisticated, cohesive look with gold hardware and exterior stitching.