- 15

- Jan

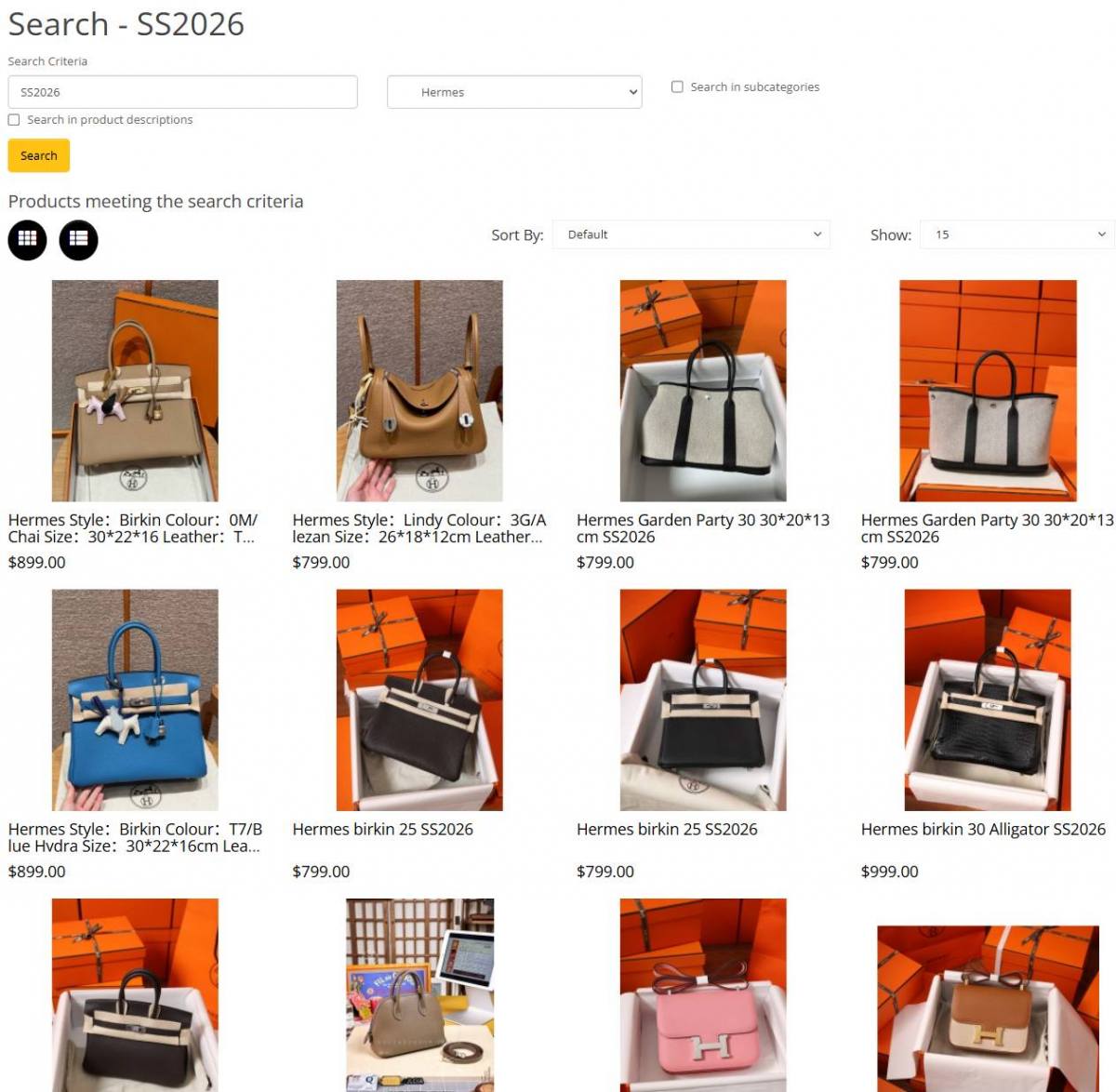

Shebag 2026 new Hermes collection (Jan 2026 updated)

It is no exaggeration to call Shebag a leather expert.

Shebag is renowned for our Chanel bags because of our long-term procurement relationship with the Haas factory in France, allowing us to obtain the exact same leather as authentic Chanel bags. However, many people are unaware that Shebag’s even rarer capability within the leather supply chain lies in our control over Hermès leather channels.

Because Hermès bags are priced higher, Shebag’s sales volume for Hermès is not as high as for Chanel. However, the leather quality of Hermès bags is a full tier above Chanel.

Today, Shebag is sharing our Hermès leather supply chain management techniques. Shebag is not afraid of copycats. Our decade-long friendships with European leather suppliers cannot be easily replaced, which is why Shebag dares to share the supply chain details behind our most hardcore, top-tier replica bags.

That’s right, most Hermès leather comes from European tanneries. Although Hermès controls the capacity of most high-quality production regions, they do not completely control the factories themselves. Factories need to survive and cannot rely solely on one major client like Hermès. However, because they are Hermès suppliers, their leather is very scarce in the market, with limited quantities and high prices.

1. Hermès’ Supply Chain Strategy: Vertical Integration

Hermès is one of the few luxury brands globally to implement high-level vertical integration of its core leather supply chain.

Regarding its two most representative calfskin systems—Epsom and Togo—Hermès does not publicly disclose specific “leather-to-tannery” correspondences. However, through long-term industrial M&A, process binding, and capacity locking, its domestic French calfskin supply is highly concentrated in a few top tanneries, most notably Tanneries d’Annonay and Tanneries du Puy.

Hermès has long adhered to a strategy of “Raw Materials Prior to Design Scale.” Especially for calfskin, by directly acquiring or deeply controlling tanneries, they ensure the leather meets brand standards regarding grain consistency, thickness range, color stability, and long-term sustainable supply. Both Epsom and Togo belong to Hermès’ “Core Structural Calfskins,” and their crust selection, tanning logic, and finishing processes are distinctly different from generic luxury brand leathers.

2. The Core Tannery: Tanneries d’Annonay

Located in the Ardèche department of France, Tanneries d’Annonay is one of the country’s oldest and most technically mature calfskin tanneries. The factory has long specialized in high-grade calfskin using a vegetable-chrome composite tanning system, possessing clear advantages in grain integrity, fiber density, and adaptability to subsequent processing.

Hermès has integrated Annonay into its own supply system to guarantee the long-term stable supply of high-grade calfskin.

- It is widely recognized in the industry that for Epsom and Togo, Hermès relies heavily on the “Top-Tier French Calfskin Crust Capability” represented by Annonay.

- Especially in the Togo system (which demands extreme control over hide size, thickness gradients, and natural shrinkage behavior), Annonay’s base crust quality is seen as the critical support.

3. The Core Tannery: Tanneries du Puy

Located in central France, Tanneries du Puy has long been famous for high-grade full-grain calfskin and holds an extremely high reputation in the European high-end footwear and leather goods sectors. This factory has also been acquired by Hermès, becoming an important component of its vertical integration system.

In common parlance among industry channels and material traders, Epsom leather is often directly labeled as “du Puy French Calfskin.”

- While not officially disclosed by Hermès, this reflects du Puy’s strong process binding attributes within the embossed calfskin system.

- du Puy’s advantages in surface flatness, finish uniformity, and post-embossing grain stability make it extremely suitable for leather types like Epsom that require high structure, scratch resistance, and shape stability.

4. Supply Chain Structure Summary

Structurally, there is no public, fixed correspondence that “one Hermès leather comes only from one tannery” for Epsom and Togo. However, within the French domestic calfskin system, core capabilities are highly concentrated between Tanneries d’Annonay and Tanneries du Puy.

- For Epsom (Embossed Calfskin): It demands extreme flatness and grain locking capability. du Puy has strong process compatibility here, while Annonay provides equivalent-level calfskin base capabilities as a supplement and redundancy guarantee.

- For Togo (Natural Shrink Calfskin): It demands control over raw fiber structure and grain tension. The industry generally attributes the core French sourcing capability to the top-tier calfskin tanning systems represented by Annonay and du Puy, rather than a single tannery.